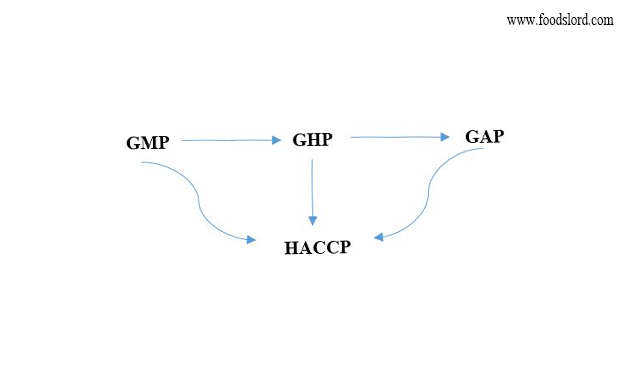

GHP standard is the short form of Good Hygiene Practice and the first step to hygiene management and is used in the whole food supply chain. GHP concerns about hygiene management in the food supply chain, workers’ hygiene practices, sanitation facilities, pest control, and preventing physical and chemical pollutions. GHP is the prerequisite of other standards including GAP, HACCP, and ISO 22000. In addition, GMP is the prerequisite of GHP that is explained in another article, and all GMP, GHP, and GAP are the prerequisites of HACCP that will be explained in another article on our website.

GHP standard in food industry

GHP addresses food safety by analyzing the hazards. The hazard analysis by GHP includes preventing contamination by people while harvesting, during manufacturing, preparation, raw materials and ingredients of processed foods, and cleaning the work, storage, and display environment. The hazard resources include the water used in the food industry, foodborne pathogens, food processing contamination, and foods contact surfaces. It should be noticed that controlling all hazards in micro dimensions is not possible by GHP requirements alone, and more precise scrutiny is implemented by HACCP.

The controlling dimensions in GHP as follows:

Environment control

First, the potential contamination sources should be detected. The food processing industrial unit should not be in a contaminated place, not near the toxic place or offensive odors, far from wastewater discharge, chemical residues, or any other resources producing the hazardous and toxic materials.

Food process control

The produced food should be sustainable. The raw material and ingredients of the processed foods should be checked according to the contamination in soil, water, fertilizers pesticides, and other primary production levels. In addition, the food sources should be tested not to have foodborne agents. Furthermore, the maintenance and storage condition of foods is important and should be controlled.

Handling, storage, and transportation

After checking the origin of raw material, and processing steps in the factory, another important part of controlling is the storage and transportation of the final product. The food should be stored hygienically far from the hazardous and non-edible kinds of stuff which may bring pollution or toxicity to foods. This pollution can be made by chemical, physical, microbiological, fertilizers, or toxic resources.

Considering the personal hygiene

All facilities in factory site, warehouses, personnel clothes, equipment, and surfaces should be cleaned and pass the hygiene permission. In addition, the employees should consider their health. The proper temperature should be considered in all seasons to have durable foods while storage in addition to the humidity of the environment and air conditioning. Therefore, good ventilation is essential.

Ref: