Cold plasma technology is a modern non conventional technique especially in food industry. Plasma is 99% of the whole universe matters. It is the fourth state of substances after solid, liquid, and gas. If we heat the gas state, it will change into plasma. Plasma is a state full of electrons, charged atoms, neutral atoms, and free radicals.

In this article we’ve talked about

Cold plasma, also called non-equilibrium plasma, is the state where the components have different temperatures in a way that neutral atoms, the greatest part, have room temperature and electrons, the lowest part, have higher temperatures of more than 10,000K. Cold plasma is at room temperature.

How to produce cold plasma?

Cold plasma is produced by applying electrical energy to inert gases including helium, argon, purified nitrogen, oxygen, and krypton. Two types of cold plasma are produced. The first one is producing high-temperature electrons at room temperature and pressure, and the second cold plasma is the one producing many reactive species while facing an open environment.

Application of cold plasma

Cold plasma is used for teeth treatment, skincare, sterilization of medical devices, surface modification, packing process, water and air purification, cancer treatment, and so on. Cold plasma is used in a valid range and has a diversity of applications in addition to affordability and cost-efficiency. This new technology is so interesting for users, particularly in the food industries.

Application of cold plasma in food industries

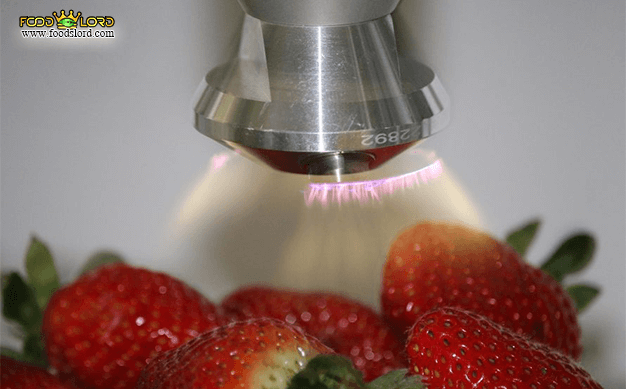

Cold plasma is a new nonthermal food processing technology that uses the energy of electrons and an inert gas such as air or helium which completely covers the foods, packages, and tools in food industries to fight the microbes by the produced free radicals and charged electrons. The areas of cold plasma technology applications in the food industry include meats, poultry, fresh and dried fruits, fresh and dried vegetables, packages, processing tools and lines, nuts, herbs, seeds, pulses, and spices.

This is a flexible sanitizing technic that uses electric power and inert and noble gases such as air, oxygen, nitrogen, and helium to produce the charged electrons to shot on the surface and damage the microbial loads to provide sanitary and sterilize the surfaces and goods.

Effect of cold plasma on food quality

The microbial load of food products can be eliminated by different physical and chemical technics or chemical compounds. In addition, physical technics such as food irradiation can be effective to increase the shelf life of the products and remove microorganisms. However, cold plasma is one of the affordable and alternative tools for food decontamination. One advantage of using cold plasma is due to its cold nature with no physical, chemical, nutritional, fundamental, and sensory impacts on foods.

Ref: